Inspect the Crucible carefully immediately after receipt as well as before taking into use. Care should be taken that glaze / protective coat do not get damaged, otherwise life will be affected.

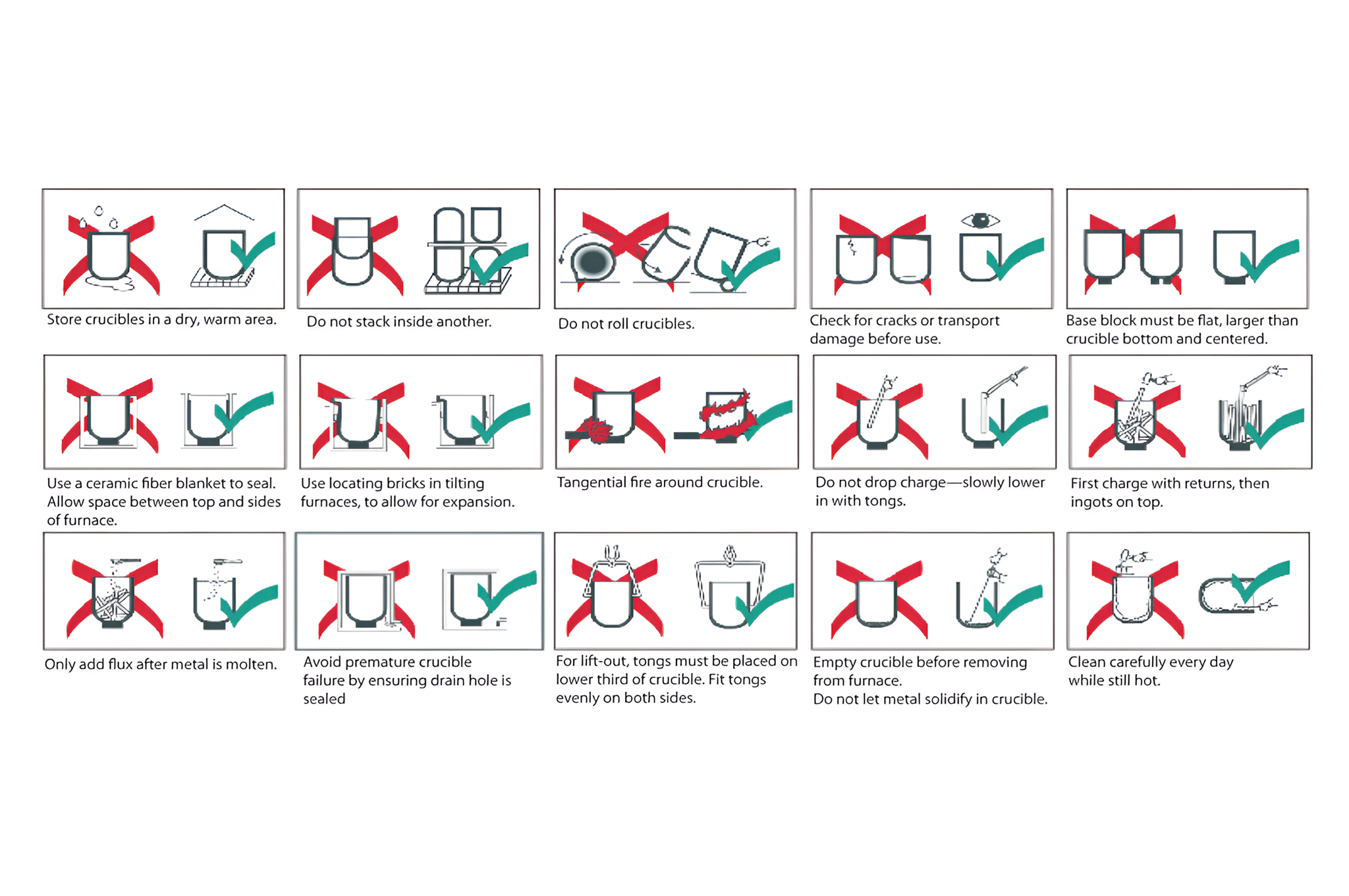

Store Crucibles in a warm and dry place. Store them on wooden pallets freely.

1.Check the condition of inside refractory lining. Uneven refractory lining in damaged form may

deflect the flame and result in more heating time and fuel consumption.

2.Remove loose debris from the sides and bottom of the furnace. Ensure that no Carbon- deposition

takes place in front of burner.

3.Check the drain hole and its flap periodically for its effectiveness.

4.Maintain proper records of fuel consumption to monitor the condition of furnace and Crucible.

5.Calibrate the thermocouples periodically.

6.Check the flame condition and its length by test firing outside.

7.Burner nozzle to be cleaned with compressed air periodically since use of hard wires might

increase the nozzle aperture.

8.Quality of coke and iron grates should be checked.

9.Condition of heating elements to be checked.

10.Check the dimension of furnace for proper gap.

It is very difficult to discuss all aspects of cares to be taken in installation of Crucibles since requirement changes with the change of furnace and change of Crucible shape. What is applicable in one case, may not be necessary in other case. Therefore, it is utmost necessary to understand the purpose. Few cares described hereunder should be taken wherever necessary

Stand should be used preferably of same material as that of Crucible to ensure

uniform heating of the bottom of the Crucible and to minimize undesired thermal strains. Stand should

confirm in diameter to the corresponding size of Crucible base in order to provide adequate support.

It is recommended to have height of the stand so that the top of stand and the centre line of flame

coincide with each other.

Install the stand firmly at the centre of the furnace.

The stand must have flat surface and it must be ensured that no foreign solid fragments fall between

the Crucible and Stand.

In oil fired Bale-out furnace, since it is desired to rotate the Crucible every week, some non sticky

material like asbestos sheet or coke powder should be placed. Similarly it should be put in lift-out

furnace for easy removal. Whereas it should be fixed firmly with high conducting patching Cement in

case of tilting furnace for better gripping.

Place the Crucible carefully on the stand without hitting with furnace lining, etc. Locate it centrally.

Required grip bricks should be placed leaving expansion gaps of about 3 mm. In case of less or no gap, Crucible will develop crack.

Crucible should be preheated to red hot condition before charging. Most common

cause for early failure is thermal shock. Carbon-Bonded SiC Crucibles can absorb more thermal shock

than Clay - Graphite Crucibles. Hence, preheating schedule should be designed suitably depending upon

the following factors.

1.Whether Clay-Graphite Crucible or Silicon Carbide Crucible?

2.Whether new Crucible or Old Crucible?

3.Whether new Furnace or Old Furnace?

4.Size of Crucible?

5.Type of heating system, etc.?